Practice Ground

Practice Ground is a humble home situated in the foothills of Wollemi National Park, on Wiradjuri Country. Conceived as a custom prefabricated build, it forms an extension of our Minima suite, linking four pavilions to form one home.

The clients are a busy couple who travel frequently, so Practice Ground was envisaged in counterpoint to this lifestyle, as a place for retreat. The site is in a former shale mining region and contains traces of this industrial past.

The clients’ site vision was, and continues to be, anchored in generosity and repair. They are now regenerating tracts of native bushland across the site, and are developing an artist’s residency program for visiting guests.

Type

New Home

Location

Glen Davis

Country

Wiradjuri Country

Status

Complete

Completion

2024

Builder

FabPreFab

Engineer

SDA Structures

Photographer

Saskia Wilson

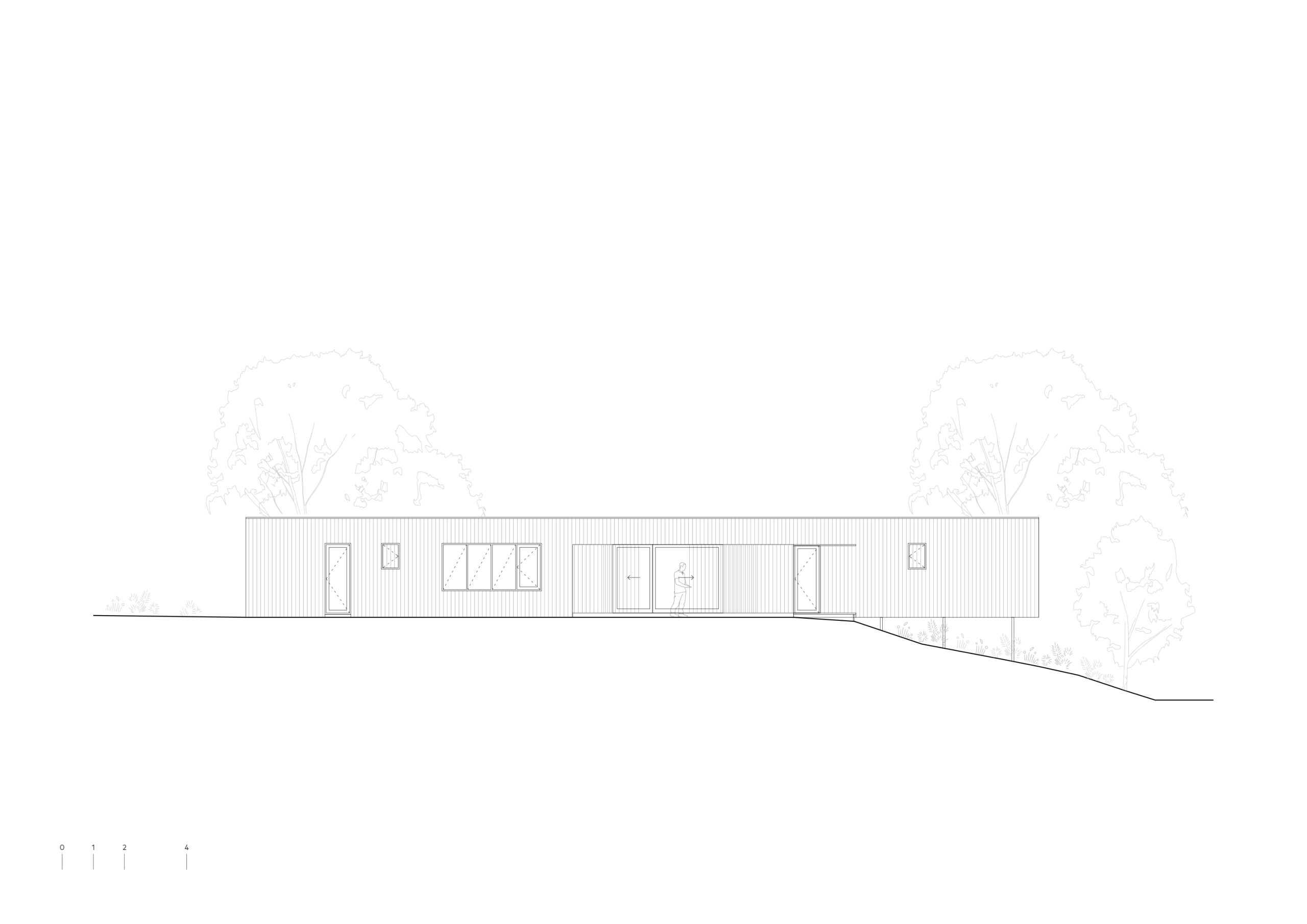

The house itself is perched on an escarpment, looking out across the valley. The rooms are arranged in a single, slender bar. The decision to stretch the home along the contour means each room enjoys the view and northern sun, while a slender footprint aids cross ventilation. This positioning also makes the most of existing site qualities, while preserving surrounding trees and outcrops. The home is placed alongside a clearing, significantly minimising groundworks. A nearby relic, an old brick fireplace, has also been appropriated as an external hearth.

Entry is via this northern courtyard, into a small vestibule. From there, the rooms are strung in simple progression. The main living spaces are placed in the centre of the home and include a generous kitchen and eat-in table, and a cosy sitting area, equipped with a built-in seat. This is where guests come together to enjoy meals and socialise. Bedrooms and bathrooms bookend the plan, allowing for privacy, independence and rest.

The compact floor plan is complimented by generous openings, which frame and expand into this astonishing landscape. Sliding doors and timber screens, and casement openings, can be opened to admit breezes and welcome warmth inside. Each room is cross-ventilated, and the construction is airtight and highly insulated. As such, the house is comfortable, with minor active heating and cooling available for more extreme days.

Practice Ground was designed to have extremely low site and environmental impacts. This begins with the commitment to this project as a prefabricated, modular dwelling. Practice Ground was manufactured off-site, minimising waste and creating material and energy efficiencies. This significantly reduces site degradation and pollution, and removes the need for skip bins worth of offcuts to be sent to landfill.

The main structure is comprised of cross-laminated timber, or CLT, panels. These panels are precision cut, before being factory assembled into modules. Windows and doors slot seamlessly into this jigsaw-puzzle. The modules were then clad with local hardwoods. Inside, the CLT is revealed and celebrated, displaying the its inherent warmth and crafted quality.

This unique construction system is an offshoot of Minima, an ongoing collaboration with the building team at FabPreFab, our CLT fabricator, and structural engineer. Minima is built on a vision to craft homes that maximise material efficiencies and minimise waste, without abandoning architectural delight.

There are other environmental benefits to this system: for example, our method of rigid modular construction allows homes to be removed, or reused, in the future, or to be disassembled and recycled. The homes, including Practice Ground, rest upon slender, removeable screw pile footings, which can be placed on site without any concrete. At Practice Ground, the result is a low-carbon, low-impact build, removeable without a trace.

This building method is also an alternative construction pathway, especially suited to isolated areas, where trades and materials are scarce and quality control can be challenging. This is, in fact, why the clients initially approached us: the project was becoming unviable as a custom build due to escalating costs. Undertaking a factory build, and delivering modules to site, not only afforded them financial and time assurances, but reduced the costs associated with material providence, transport, and remote workers, who often attract labour premiums. In the end, the project was delivered for a square metre rate well below the norm in Sydney and its surrounds.

Practice Ground exemplifies how rural and remote housing can be delivered in environmentally sensitive areas, while also minimising carbon impacts and waste. As an extension of our ongoing collaboration with FabPreFab, this home shows how factory-built housing can emblemise material economy, carbon sequestration and landscape preservation, while remaining personalised and site-specific.